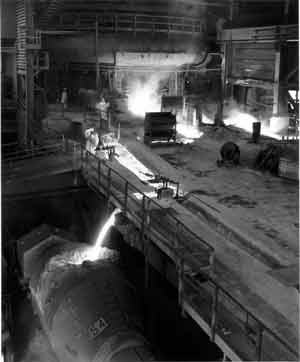

The following is a brief chronology of Bethlehem Steel from 1857 to 1998. In

1857, the Saucona Iron Company was formed and eventually evolved into the Bethlehem

Steel Company (after a series of name changes) in 1899. This company was extremely

influential during the industrial revolution of the United States. Through the

years, Bethlehem Steel gained control of various steel plants and ship building

companies, helping to increase the profits of the company. For both World War

I and World War II, Bethlehem Steel was involved in the production of vast quantities

of ships, armor, ordnance, guns, and munitions for the United States and her

allies. The company was also involved in the formation of the steel for various

buildings, including the Golden Gate Bridge, Rockefeller Plaza, and the US Supreme

Court Building. Although more than 10 million tons of steel were imported into

the United States in 1965, Bethlehem Steel still managed to reach a record high

of producing 23.7 million tons of raw steel in 1973. In 1978, over 28 million

tons of steel were imported. In 1982, Bethlehem Steel began to lose money. Over

the next 5 years, half of the employees were laid off and company branches began

to be shut down. In 1995, steel making finally ceased in the Bethlehem plant.

In 1996, Bethlehem Works was formed and began to plan ways to redevelop portions

of the Bethlehem Plant.

Click

here for some current pictures of Bethlehem Steel

A Brief Chronology of Bethlehem Steel

1857 - Earliest predecessor company, Saucona Iron Company, is formed in South Bethlehem, PA.

1859 - Company falls under the control of the Lehigh Valley Railroad. Robert H. Sayre, Chief Engineer and General Superintendent of the Lehigh Valley Railroad, will guide the destiny of the company for the next four decades.

1859 - Company is re-organized as the Bethlehem Rolling Mill and Iron Company.

First action of the initial Board meeting is to hire John Fritz, inventor of

the "three high rail mill." John Fritz’s "three high rail

mill" will provide the Lehigh Valley and other railroads with economic

high quality iron rails.

1860-63 — Company’s plant is laid out by Robert H. Sayre and John Fritz. It is located at the junction of the Lehigh Valley and North Pennsylvania Railroads, a site that will enable its products to be easily shipped to both New York and Philadelphia.

1859 — Name of company is changed to Bethlehem Iron Company.

1863 — Company produces first iron railroad rails.

1863-64 — John Fritz designs a rail re-rolling mill which is bought by the Bethlehem Iron Company. It is erected at Chattanooga by the US government and it repairs the railroad rails needed to supply General Sherman’s army as it advances to Atlanta.

1873 — Company produces its first Bessemer steel railroad rails. Its steelmaking and rail mill, which was designed by John Fritz, is the first attempt to achieve integrated steel production in America

1886 — Facilities, such as open hearth furnaces, forging hammers, presses, and large machine shops, are added to the plant to produce ordnance and iron plate for the US Navy. Bethlehem Iron thus becomes the birthplace of the modern American defense industry.

1893 — John Fritz retires and becomes elder spokesman and statesman of the American iron and steel industry.

1893-95 — Company successfully enters international armaments and armor markets.

1898 — Ships of the US Navy that are armed with Bethlehem Iron ordnance and armor plate play a large role in winning the Spanish-American War. At the conclusion of this conflict, the United States possessed an overseas empire.

1899 — The Bethlehem Iron Company evolves into the Bethlehem Steel Company. Robert H. Sayre retires and Eugene G. Grace, who will later become President and Chairman of the Bethlehem Steel Corporation, joins the company after retiring from Lehigh University.

1901 — Charles M. Schwab is instrumental in formation of US Steel Corporation and is named its first president.

1903 — C.M. Schwab resigns from US Steel.

1904 — C.M. Schwab forms Bethlehem Steel Corporation, becoming president and chairman of the board. Facilities include steel plant in South Bethlehem, iron mills in Cuba and shipyards on East and West Coasts.

1908 — Bethlehem’s new Grey rolling mill begins production of the nation’s first wide-flange structural section revolutionizing building construction and making possible the age of the skyscrapers and the long span bridges.

1910 — Bethlehem becomes the target of a violent work stoppage that involves the first intervention of the Pennsylvania State Police in labor disputes.

1913 — Bethlehem Steel acquires Fore River Shipbuilding Co. at Quincy, MA and increases its ability to produce large warships.

1914 — At beginning of World War I, Bethlehem has annual steelmaking capacity of 1.1 million tons and employs 15,600 people. During the war, Bethlehem produces vast amounts of ships, armor, ordnance, guns, and munitions for the US and allied forces.

1916 — E.G. Grace named president of Bethlehem with C.M. Schwab continuing chairman of the board. Bethlehem acquires American Iron and Steel Mfg., Co., Pennsylvania Steel Co. and Maryland Steel Co. with steel operations in Lebanon and Steelton, PA, Sparrows Point, Md., and coal mines in West Virginia and iron ore mills in Pennsylvania.

1918 — Between April 1917 and the Armistice in November 1918, Bethlehem

Steel produced more than 65% of the total number of finished artillery pieces

manufactured by all the allied nations. In order to achieve these miracles of

productivity, the company spent more than $102,000,000 for the construction

of new facilities at the Bethlehem plant. For the first time, a large number

of women are employed at Bethlehem’s plants.

1922 — Bethlehem acquires Lackawanna Steel Co. with steel operations in Lackawanna, NY and iron mines in the Great Lakes region.

1923 — Bethlehem Steel acquires Cambria Steel Company and all but the heavy forging operations of Midvale Steel and Ordnance Company. These mergers give Bethlehem additional steel operations and coal mines in Johnstown, PA area.

1925 — Bethlehem’s steelmaking capacity grows to 8.5 million tons a year and employment to more than 60, 000. USS Lexington, America’s first battle-worthy aircraft carrier, is launched at Bethlehem’s Fore River shipyard. Converted from battle cruiser hulls, the Lexington and her sister ship, Saratoga, are fast vessels capable of deploying more than 100 planes and both will play a prominent part in the Pacific battles of WWII.

1930 — Bethlehem Steel enters the Pacific Coast market with the acquisition

of steel plants in Settles, San Francisco, and Los Angeles.

1931 — Bethlehem Steel acquires McClintic-Marshall Corp., a major fabricator and erector of bridges and buildings. During the decade, Bethlehem fabricates the steelwork for such landmark structures such as the Golden Gate Bridge, George Washington Bridge, Rockefeller Plaza, Waldorf-Astoria, Chicago Merchandise Mart and the U.S. Supreme Court Building.

1939 — C.M. Schwab dies.

1941 - After a short but extremely violent strike, Bethlehem Steel accepts employee representation by the United Steelworkers of America.

United States enters World War II, and Bethlehem Steel’s operations shift

to all-out war production of steel plate for ships and tanks, structural steel

for defense plants and forgings for guns, shells, and aircraft engines. Bethlehem

Steel’s 15 shipyards build 1,121 ships, more than any other shipbuilder

in World War II. At the peak of production, Bethlehem Steel employs 300,000

people, 180,000 of them in shipbuilding.

1941-45 — Among the famous warships that are launched by Bethlehem Steel

yards are the Battleship USS Massachusetts and the carriers USS Hancock and

Lexington (named after her sunken predecessor). Bethlehem steel supplies ordnance,

armor plate, and propulsion machinery forging for all classes of American World

War II battleships, including the USS Missouri. New shipyards are constructed

in Hingham, MA and Fairfield, MD to build destroyer escorts and liberty ships,

respectively. As during World War I, large numbers of women workers were employed

at Bethlehem Steel’s plants and shipyards.

1945 — E.G Grace elected chairman. Bethlehem Steel begins programs to expand capacity to meet post-war demand for steel.

1957 — Bethlehem employs 165,000 people, a post-World War II high.

1958 — Bethlehem’s annual steelmaking capacity reaches 23 million tons, almost double the 12.9 million tons of the mid 1940s.

1959 — Bethlehem Steel is plagued by a lengthy strike, the outcome of which redefines the relationship between the Corporation and the Union. Homer Research Laboratories open to produce new products such as quenched and tempered plate, tin-free steel, and new generations of coated steel plates.

1960 — Arthur B. Homer, head of Bethlehem Steel’s World War II shipbuilding program, is elected chairman.

1962 — Bethlehem Steel announces it will build a major integrated steel plant in Burns Harbor, IN, the most ambitious single project in its history to produce sheet and plate steel for the fast-growing Midwest market. Today, Burns Harbor is Bethlehem Steel’s largest, most efficient plant with 5.3 million tons capacity.

1964 — Edmund F. Martin is elected chairman. The Burns Harbor plant begins

production and Bethlehem Steel’s first basic oxygen furnaces begin steelmaking

in Lackawanna.

1965 — For the first time, more than 10 million tons of foreign steel are imported into the United States.

1966 — Bethlehem Steel fabricates steel for Madison Square Garden, Newport

Bridge, and second Delaware Memorial Bridge.

1970 — Stewart S. Cort elected chairman of Bethlehem Steel.

1973 — Bethlehem Steel produces 23.7 million tons of raw steel and ships 16.3 million tons of finished steel — both records — and reports net income of $207 million.

1974 — Lewis W. Foy is elected chairman.

1975 — Capital expenditures for the year amount to a record $674 million. Bethlehem Steel's first continuous caster begins production at Burns Harbor.

1976 — Bethlehem Steel shuts down its Fabricated Steel Construction Division, the successor to the McClintic Marshall Corp.

1977 — Bethlehem Steel reduces steelmaking capacity at Lackawanna and Johnstown. It begins a series of layoffs that are the harbingers of an extended period of downsizing.

1978 — More than 21 million tons of steel are imported.

1980 — Donald H. Trautlein is elected chairman.

1981 — Bethlehem Steel's sales reach a record $7.3 billion.

1982 — Bethlehem Steel reports a record loss of $1.5 billion, the first of five years of losses as the steel industry goes through a period of unprecedented restructuring. Bethlehem Steel eliminates steelmaking at Lackawanna and shuts down or sells other plants, mills, mines and shipyards. Total employment is reduced by more than half in the next five years.

1984 — Steel imports into the United States climb to a record 26 million tons and Bethlehem Steel and the United Steelworkers Union successfully file a 201 Petition under U.S. trade laws.

1986 — Walter F. Williams is elected chairman. Bethlehem Steel concentrates its resources on making its steel operations competitive, restructuring its businesses and rebuilding its financial strength. New continuous casters begin production at Sparrows Point and Burns Harbor.

1988 — Bethlehem Steel reports record net income of $426 million.

1989 — Bethlehem Steel announces it will build three new hot-dip galvanizing lines in Burns Harbor, Sparrows Point and in the southern United States. Work proceeds on complete modernization of Sparrows Point hot-strip mill.

1990 — Bethlehem Steel restructures its structural and rail operations.

1992 — Curtis H. Barnette elected chairman. Steel plants established as

individual business units that are responsible for production, marketing and

financial performance. Bethlehem continues restructuring, exiting the bar, rod

and wire business.

1993 — New galvanizing lines begin production at Burns Harbor and Sparrows

Point. Bethlehem and USWA negotiate a six-year agreement.

1994 — Major capital improvements include new coke oven battery and coal

injection facility at Burns Harbor and new electric furnace and head-hardening

rail line at Pennsylvania Steel Technologies.

1995 — Bethlehem Structural Products and BethForge undergo major transition, discontinuing steelmaking operations.

1996 — Bethlehem Steel announces the formation of Bethlehem Works, a subsidiary which will preserve, interpret, and redevelop portions of the Bethlehem Plant. Included in the Bethlehem Works’ plan is the creation of a National Museum of American Industry in collaboration with the Smithsonian Institute. To improve financial performance and stockholder value, Bethlehem undertakes comprehensive restructuring plan involving sale or shutdown of unprofitable businesses and improved competitiveness of core steel operations at Burns Harbor, Sparrows Point, and Pennsylvania Steel (Steelton).

1997 — BethForge and CENTEC Divisions of the Bethlehem plant are sold to the West Homestead Engineering and Manufacturing Company. Bethlehem Steel’s Steelton Plant supplies ingots to this operation. Bethlehem also sells Bethship, Bethforge, CENTEC and coal mining interests, and ends its production of structural shapes. Announces $300-million investment in new cold rolling mill at Sparrows Point.

1998 — The Coke Works shuts down, ending all Bethlehem Steel production activities at the Bethlehem plant. Bethlehem Steel merges with Lukens Inc. to become a premier plate producer in North America.

(Lance Metz)