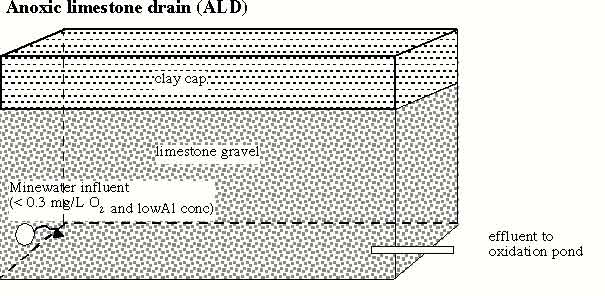

Diagram courtesy of Carl S. Kirby, Bucknell University

So far, BAMR has completed construction on two separate

facilities using anoxic limestone drains

(ALD’s) and has partially funded a third site. The first was constructed

on Cucumber Run in Fayette County, primarily within Ohiopyle State Park.

This was a rehabilitation of a facility constructed under Operation

Scarlift. Flows from two separate sources were directed into ALD’s

prior to being discharged into an existing aerobic

wetland. This facility has been operating since 1997 and has been the

most maintenance free facility to date. The ALD’s were of a somewhat

unique construction to address aluminum levels in the raw water that

became elevated during the latter phases of design of this project.

The ALD’s were teardrop shaped, with the widest portion being on

the upslope end near the source, and were oversized. They were constructed

on relatively steep slopes, rather than the usual, nearly level construction,

and clay barriers were placed within the drains to help keep more of

the drain flooded. While both drains have air seals at the outlet, neither

is entirely flooded, so some air is present in the drains. These drains

are likely retaining some aluminum, although they were not constructed

with sampling ports at the head of the drains, so we are unable to monitor

raw water quality. However, no aluminum is discharging from the drains,

so it is likely they are retaining aluminum. While only time will tell

for sure how effective this design has been in preventing plugging by

aluminum, so far the results have been good. Other ALD’s are known

to have plugged from aluminum within months of construction, so this

design has shown promise in its operation. Cucumber Falls, a popular

tourist attraction downstream of DEP’s system, has improved aesthetically

(no iron staining) since the system has been in operation. A macroinvertebrate

survey has also shown considerable improvement in Cucumber Run.

A second ALD system has been constructed by BAMR on a site where bonds

were forfeited along Glade Run in Armstrong County. This site, known

as Darmac 14, was completed in the fall of 1998. Prior to construction

of BAMR’s facilities, a limestone trench constructed by the former

coal operator was intercepting and collecting AMD emanating from a reclaimed

surface mine site. Sampling of a small discharge not being intercepted

indicated a net alkaline discharge with elevated iron and manganese

concentrations. The flow from the trench was directed into an ALD during

construction. The discharge from the ALD then enters a settling pond/aerobic

wetland.

The decision to install an ALD was made for several reasons, in spite

of the apparent net alkaline conditions. There was concern that some

of the water being intercepted by the limestone trench may be net acidic

prior to the contact with the limestone, and there was concern about

the longevity of the trench as it was currently constructed – how

long it would take to deplete or armor the limestone in an open channel

(U. S. Bureau of Mines, 1995). While there were problems in construction

attempting to capture all the flow, post-construction stream data indicates

that this was largely successful. The treatment system has been operating

very effectively, with a strongly net alkaline discharge and low metals

concentrations.

An ALD system that was partially funded but not constructed by BAMR

has had considerable problems with aluminum. This project, known as

the Conifer project, was constructed along Beaver Run in Jefferson County.

A year of background sampling showed aluminum in the range of 2 mg/L.

In order to prevent plugging of the drain, the ALD was designed with

a perforated manifold system to spread the flow over a large surface

area at the inlet, and a relatively wide drain was constructed (80’

wide by 250’ long [24.3 m by 76 m]). The system was completed in

the fall of 1998. Later that year a drought caused the deep mine discharge

to dry up completely. When the flow came back in early 1999, aluminum

levels had increased considerably and have stayed much higher than was

previously measured. The ALD plugged soon after the flow came back.

Fortunately, the design of the system allowed for access to the inlet

of the ALD, where flows could be backed up in the mine using a water

level control structure, and a pump was used to “backwash”

the ALD. This, and the resultant flushing when the drainage was directed

back into the drain, allowed the drain to function for about six months.

After that time period, the process needed to be repeated. Subsequent

backwashing and flushing has resulted in decreasing time periods until

the ALD plugs again. Recently, a decision was made to excavate the inlet

portion of the ALD to determine the location of the plugging. If it

is found that all the plugging is occurring within the first few inches

of the drain, the manifold will be removed and replaced by a pipe to

concentrate a higher velocity flow over a smaller area to see if this

corrects the plugging problem (Hein, 2000).

Return

to AMD Stakeholders' page